To prevent the engine from coming to a standstill below a minimum crankshaft speed, it must be supplied with some fuel-air mixture, the so-called idle throttle, when idling.

If the accelerator pedal is not pressed, the throttle valve is completely closed. The engine would stall, as no ignitable fuel-air mixture is formed. However, air can flow through the duct into the manifold and thus form the mixture required for idling.

On engines with D-Jetronic, the idle speed is regulated with the idle speed adjustment screw or recirculation adjustment screw.

This screw is screwed into the manifold under the hose from the air filter to the manifold and increases or decreases the flow cross-section of a duct that bypasses the throttle valve. This regulation means that the engine receives more or less air, which increases or reduces the idling speed.

- More air = idling speed is increased

- Less air = idling speed is reduced

The idling speed is set slightly higher than absolutely necessary so that less vibration occurs or a sudden change to load operation does not cause the engine to stall.

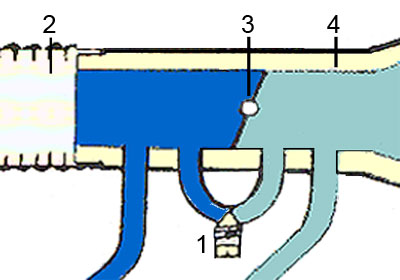

Fig.: Schematic diagram of the duct for the air supply.

(1) Adjusting screw; (2) Air hose; (3) Throttle valve; (4) Induction manifold.

Fig.: An adjusting screw with a conical tip regulates the air flow through the duct.

Fig.: The air circulation adjusting screw is secured with the lock nut, a hexagon nut (3/8UNCx5.6) to prevent loosening due to vibrations.

Tool: 9/16 inch open-end spanner.

Setting the idle speed

- Heat the engine to an operating temperature of around 80 °C so that the auxiliary air slide valve is definitely fully closed.

- Connect an external rev counter, the rev counter on the dashboard is too inaccurate.

- Carefully remove the intake hose between the air filter and the manifold on the manifold.

- Check that the auxiliary air slide valve is fully closed. To do this, pull off the hose between the additional air slide valve and the manifold at the connection piece and seal the connection piece by hand. The speed must not change significantly during this process. Otherwise the engine is not yet warm enough or the additional air slide valve is defective. Reconnect the hose to the manifold.

- Set the idling speed to 900 rpm (mechanical gearbox) or 800 rpm (automatic gearbox) using the adjusting screw. Secure the screw with a lock nut (SW 9/16). If the speed cannot be reduced sufficiently, the basic setting of the throttle valve must be checked.

- Reconnect the hose between the air filter and manifold to the manifold.